It is characterised by its high level of knowledge and experience and is a reference in the Spanish market.

Services line

DF also is a turnkey contractor for biomass and cogeneration plants, pellet plants, smart warehouses, as well as providing the construction, assembly, operation and maintenance of wind farms.

The main guarantees that DF provides in the services field for power generation and industrial facilities are a team of professionals that are highly specialized in all the areas that the services field requires and a constant effort in the specialized training of its workers.

DF Operaciones y Montajes (DFOM)

DF Operaciones y Montajes (DFOM) is a subsidiary of the DF Group which has integrated by absorption the companies Felguera Montajes y Mantenimiento (FMM), Felguera Revestimientos (Feresa), Operaciones y Mantenimiento (Opemasa) and Montajes Eléctricos Industriales (MEI).

DFOM is part of the Specialised Services segment and encompasses electromechanical assembly, thermal, cryogenic and acoustic insulation, commissioning, operation and maintenance of power generation plants and industrial facilities.

Activities

- Conventional coal-fired steam generators.

- Heat Recovery Steam Generators (HRSG) for combined cycle plants

- Alloy piping for water-steam cycles at power generation plants.

- Forced piping at hydroelectric plants, turbines, penstocks and auxiliary equipment.

- FCC (refineries).

- Blast furnaces (steel industry).

- Wind farms (complete management of the project including construction of the wind turbines).

Heat, cryogenic and sound.

Specialised in heat insulation of generators and turbines, piping and control equipment of power generation plants.

Authorised for the removal of asbestos (company included on the RERA – Registro de Empresas con Riesgo de Amianto – register).

The insulation methods and products used are:

- Conventional insulation.

- Blasted insulation.

- Removable linings (padding).

Works for start-up operations of all types of industrial installations, with ample experience in power generation facilities.

- Electrical, mechanical, preventive, predictive, corrective and modifying maintenance, with workforce residing on site.

- Maintenance at major programmed outages (overhaul and update of the installation). Specialized in coal-fired boilers, rotating equipment at power generation facilities, as well as blast furnaces and FCCs at refineries.

- Complete operation and maintenance of power generation and other industrial facilities.

- Maintenance engineering; development of complete maintenance programmes (and implementation on GMAO systems); development of general and specific O&M procedures; criticality studies of systems and equipment, and also determining the dimensions of stocks for spare parts specific to each type of facility.

- Technical audits of power generation and industrial plants.

- Comprehensive management of warehouses in power generation

plants and industrial plants. - Top level operation and maintenance of water treatment plants and effluents.

- Preventive and total maintenance of automated warehouses (electrical and mechanical, warehouse management system and warehouse control system).

- Windpower sector:

- Engineering, construction and support for start-up of the facility. O&M.

- Complete management of maintenance tasks.

- Predictive studies and quality control audits .

Duro Felguera has incorporated DFOM NETHERLANDS BV for the development of an important

O&M project in the Netherlands. All activities related to this project will be channelled through this company.

mompresa

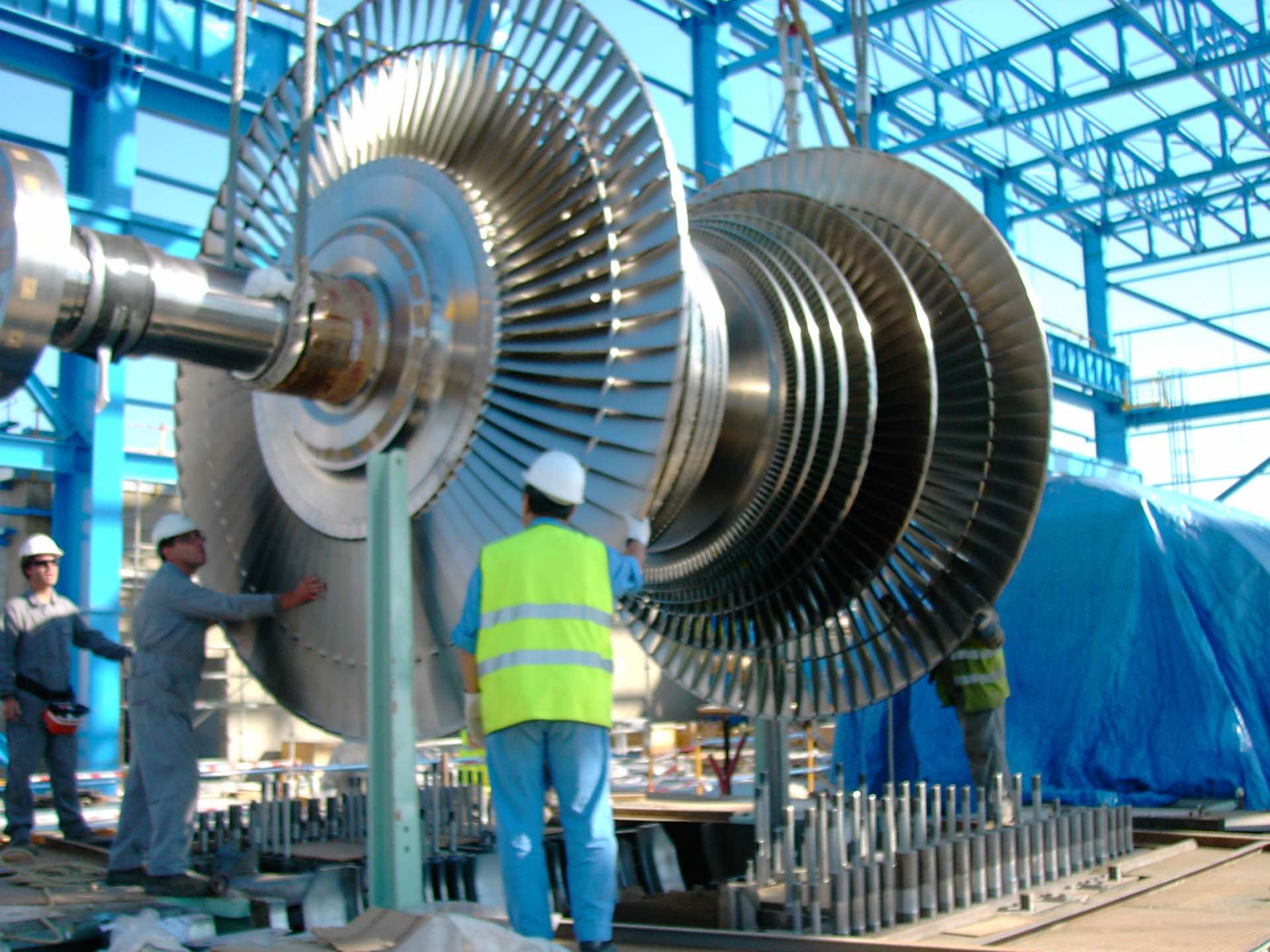

Assembly and inspection of turbogenerators

The leading company in construction, revision and overhaul of turbines, generators and auxiliary equipment at power generation facilities, as well as rotating equipment for all types of industries.

The company has worked on over 90% of all the steam turbines at power generation facilities in Spain and on many other installations in Europe and Latin America. With over 500 contracts in the last 25 years, it can currently carry out 30 interventions per year.

DF Mompresa has a training centre that uses real equipment, including a complete 160 MW steam turbine, which means situations and complex interventions can be reproduced and real cases can be recreated.

REFERENCES

Services

Injection of GCK to Blast Furnace B, Factory of Gijón

Storage and Injection to Blast Furnace A Naphthalene Diesel. Factory of Gijón

Nuclear Power Plant Ascó (2 x 1032 MW)

Costanera Thermal Power Plant (2,340 MW)

Andasol 3 Solar Thermal Power Plant (1×50 MW)

Staythorpe C Combined Cycle Power Plant (1,708 MW)

The Services Division confirms its leadership with three new contracts signed with Repsol

It is a great satisfaction for our company to accompany a large company like Repsol, which is resolutely moving towards sustainable production and the development of advanced technologies.

Successful completion of the Repsol Química shutdown in Tarragona

We have completed our work on the major shutdown of Repsol Química in Tarragona, with 60,000 hours carried out in 50 days of shutdown with 24-hour work, with no reportable safety incidents and with more than 150 people who have worked tirelessly to achieve the objective set by our client.

CONTACT

-

DF OPERACIONES Y MONTAJES

Address Parque Científico Tecnológico

C/ Ada Byron, 90

33203 Gijón, Asturias (Spain)Telephone +34 985199000 E-mail dfom@durofelguera.com -

DF MOMPRESA

Address Parque Científico Tecnológico C/ Ada Byron, 90 33203 Gijón, Asturias (Spain) Telephone +34 985679850 +34 985179505 E-mail mompresa@durofelguera.com